Interior packaging works hand in hand with the overall packaging presentation. Whenever we refer to the importance of the “unboxing experience” we are referencing not only the added appeal of inside print, but also of product display and protection. When a customer opens your box for the first time, looking to share the experience on social media, it’s important that the product is not lying in a disorganized mess from the shipping journey. A beautiful interior print will do little to offset a customer’s disappointment over receiving loose-fitting product assembled in a box without protection, that has been disrupted, moved, unsettled or possibly even damaged during transit. After all, the primary function of any packaging should be to ensure the contents arrive safely, and in one piece.

But many interior packaging solutions, though effective and ideal at high volumes for companies with spending flexibility, do not make sense for low-volume, budget conscious start-ups. Die cut inserts, for example, may require design time, complete customization, and often costly set-up fees in addition to added materials and freight charges. However, there are interior packaging options that require no tooling costs, and can add protection and stability to your product at minimal added expense.

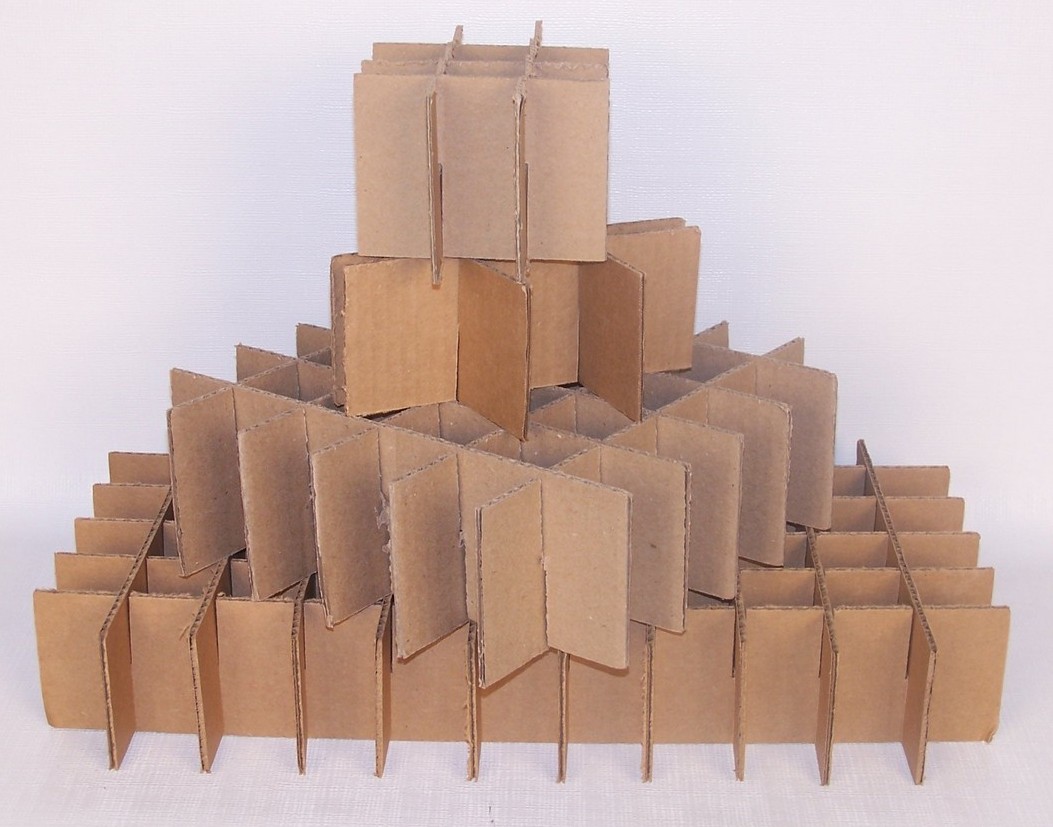

Corrugated and Paperboard Partitions and Dividers

Although they are not a stock product and are made to order, partitions DO NOT require tooling costs, and are available as a low minimum, affordable solution in a variety of options. Board grade, board color, cell arrangement, size and assembled or unassembled delivery are some of the choices to consider when selecting a partition solution that will not only add to the “unboxing experience” in terms of product presentation, but also ensure the product is kept upright, secure, stable and protected while adding reinforcement and strength to the box.

A divider is another solution when product separation is needed, creating protection while adding a ‘retail look’ when product visibility is crucial. Also available in both paperboard or corrugated, dividers are a no tooling cost solution in MOST applications. Dividers ship flat, are light weight and can reduce the need for void fill or cushioning.

Both partitions and dividers offer a better product presentation than loose void fill or bubble wrap, and are often a greener option as well. Corrugated partitions and dividers can be made from recycled content, and are always 100% recyclable.

Want to know more about Interior Packaging? If you are unsure of what packaging solution best fits your needs, don’t hesitate to ask one of our experienced branded packaging advisors. Please contact us at Salazar Packaging or call us at 630-551-1700 for a no cost, no obligation review of your specific application.

Related Posts:

https://salazarpackaging.com/balancing-protection-presentation-e-commerce-subscription-boxes/

https://salazarpackaging.com/enhance-your-consumers-experience-with-scored-pad-dividers/