We’ve covered a lot of ways to save money through structural design changes, such as right-sizing your box, changing box style/type, reducing packaging skus, adding inserts and more. But equally important are cost-saving changes that are specifically aesthetic or visual, rather than structural. Knowing what your options are and where/how price is impacted when it comes to the specifics of your mailer can be critical in deciding what savings are available to you, as well as how much you could be saving.

Are your Current Graphics Adding Cost?

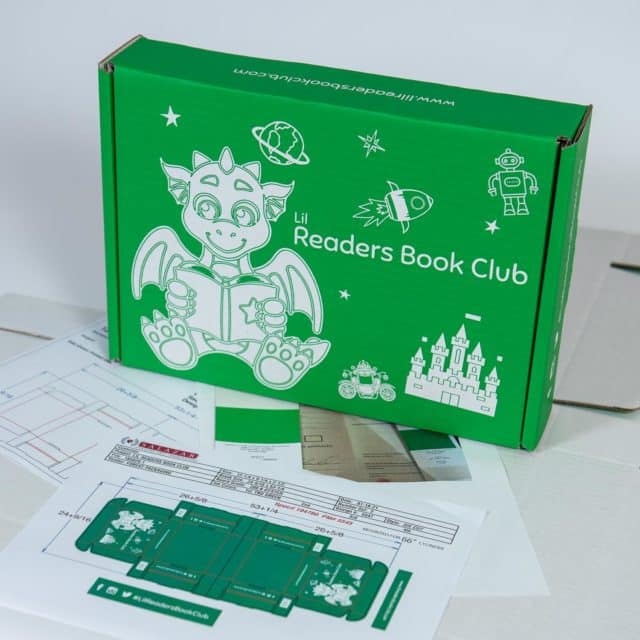

Perhaps this question should really instead be phrased “In what way(s) are my graphics impacting cost?” Flexographic printing is the lowest cost option for custom boxes. But because it is an ink direct to board printing method, there are limitations and certain factors to be considered. Are your graphics complex, such as a photo-quality image? This requires either a litho label or digital printing to achieve the desired result, which can be two or three times more expensive than flexographic printing. Other factors include gloss/finishes. Keep in mind that a flexographic print is typically a flat or matte finish, and to achieve a shiny, glossy look or feel, either a label needs to be applied, or alternatively a digital print on more expensive kemi board. Unsure of whether or not your current graphics can be printed with flexographic printing? With one look at the design, we can tell.

Consider Your Printing/Graphics Placement and Location

What you are printing will affect cost, but equally important is WHERE you are printing. Recently, one of our larger volume customers who has ordered from us for years asked us for ways to reduce the cost on their printed mailers across three sizes. We sent them pricing which only eliminated one line of text from the inside lid of their mailer, and to their surprise (and delight) this simple change resulted in a 25% price reduction per box. This is due to the fact that inside printing is an added step in the production process, so that time-savings on the machine is reflected in the total cost. Even better, they’ve already purchased the interior print plate, so if they want to add back interior printing on any of their future orders, they can do so seamlessly.

Your graphics and ink colors will typically dictate what board color is best, but in the cases where you do have options and are flexible, kraft board will typically save about 4-8% per side (inside/outside) vs. white board. Again, this is not always a feasible option, (for example if you are printing with lighter ink colors that will not print well on kraft) but kraft board is the lower cost option, the more eco-friendly option, and as an added bonus, almost always has lower lead times.

Ink Color Changes

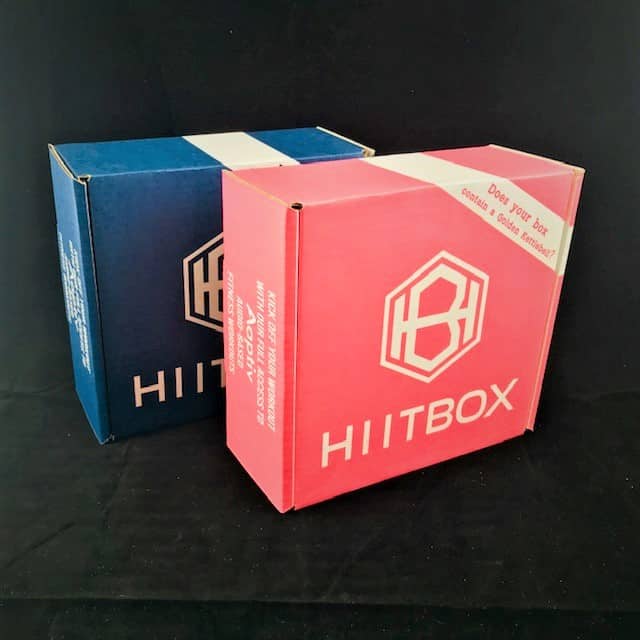

Perhaps you are not looking for full-scale design changes, but want a fresh, new look for your custom mailer without breaking the bank. Consider an ink color change. There is almost never an added cost to change your ink color. See the examples below for customers who wanted to switch things up and try a new color with their existing graphics. Whether for a one-time promotional idea, or for a more permanent change, all that is required is ink sample approvals to make the switch, and as long as the ink color you choose is not a specialty ink that would require added cost, then your per unit box pricing remains the same, while your packaging gets a makeover.

Whether your motivation is budget-related, or otherwise, if you’re looking for a change in graphics or just need to talk to an experienced industry expert, please reach out to us to begin the dialogue.

Please Contact Us Today

As always, if you have any questions, one of our branded packaging advisors is standing by to assist, with decades of experience behind them. Want to know more about custom packaging options? Please call us at 630-551-1700 or contact us via email at www.SalazarPackaging.com.

Related Posts:

https://www.globeguardproducts.com/industry-experts/save-money-in-2023-by-reducing-your-box-size/

https://www.salazarpackaging.com/e-commerce-packaging-trend-simplicity-to-reduce-cost/

https://www.salazarpackaging.com/save-money-by-using-our-stock-cutting-dies-for-dtc-packaging/